Trakonta ltd, 54031 Ukraine, Nikolaiv city, Electronnay street 81/4, E-mail: trakonta@gmail.com Tel: +380512714945; Mob, Viber: +380503180260

Electro-hydraulic crushing of animal feed

Information about the crushing of various materials by electrohydraulic impact is quite known and interesting, including in relation to animal feed. At the same time, for grinding roughage, electrohydropulse technology have significant advantages over traditional mechanical grinders. They have a higher efficiency, simplicity and longer service life of the working bodies, ease of reconfiguring the grinding mode, disinfecting feed during the grinding process, etc.

Information about the crushing of various materials by electrohydraulic impact is quite known and interesting, including in relation to animal feed. At the same time, for grinding roughage, electrohydropulse technology have significant advantages over traditional mechanical grinders. They have a higher efficiency, simplicity and longer service life of the working bodies, ease of reconfiguring the grinding mode, disinfecting feed during the grinding process, etc.

Trakonta ltd

Electro-hydraulic crushing of animal feed

Electro-hydraulic crushing of animal feed

Grinding of roughage is carried out due to the high energy of periodically generated pulsed shock waves propagating from the channel of an electric discharge in a liquid medium. In essence, an electric discharge in a liquid is one of the most effective ways to convert electrical energy into mechanical energy without intermediate links and, accordingly, with high efficiency. Electrohydraulic crushing of animal feed (slaughterhouse waste and carcasses of slaughtered fur animals) makes it possible to use them as a complete feed for fur animals, pigs and poultry. At the same time, in addition to disinfection, electrohydraulic processing ensures homogenization and an increase in the nutritional value of feed.

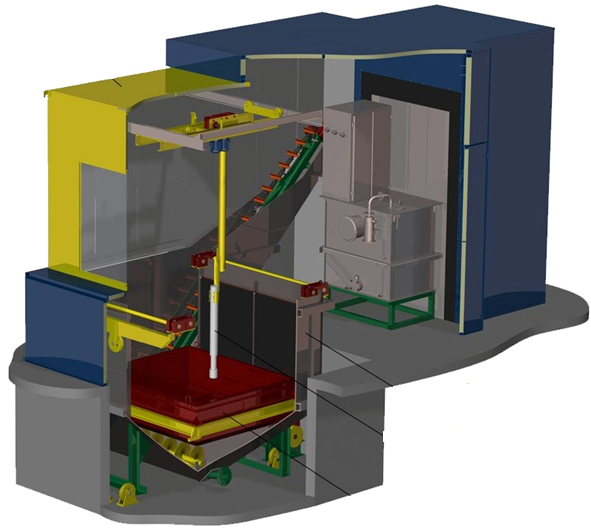

Biochemical analysis showed that the content of crude protein in slaughterhouse waste after electrohydraulic processing does not change, and the yield of crude fat increases by 15-30% due to the destruction of polymeric forms of fats and their transformation into forms that are easily digestible by animals. In addition, in the process of processing, the sharp corners of the bones of meat waste are chopped and "rounded", which also increases the quality of feed and excludes cases of injuries of the gastrointestinal tract in animals that consume this feed. Electrohydraulic processing of meat feed is carried out in crushers, similar to those used for crushing plant feed of the circulation type. Processing is carried out mainly in soft modes (micromodule 1: 0.75).

The slaughterhouse waste and carcasses of dead animals are crushed and then subjected to electrohydraulic processing to the state of a disinfected homogeneous pasty mass suitable for feeding to animals both directly in the form of a paste and in a dried form, allowing long-term storage.

As shown by the operation of an experimental electro-hydraulic installation in the Roshchinsky fur farm in the Leningrad region, fur-bearing animals willingly ate the feed processed by this method, gaining weight well. The maturation of mink fur accelerated by 5-7 days, the quality of the skins increased by 10%. The mortality of puppies in the experimental group was 5% less, and the number of puppies per female was 5 in the experimental group versus 3 in the control group. Electrohydraulic crushers for complex processing and "disinfection of meat waste from livestock farms, urban food waste, as well as peat, straw, pine needles, twig fodder and other organic products have already passed experimental testing, and in some cases, experimental industrial operation and have great prospects for wide industrial implementation.

As shown by the operation of an experimental electro-hydraulic installation in the Roshchinsky fur farm in the Leningrad region, fur-bearing animals willingly ate the feed processed by this method, gaining weight well. The maturation of mink fur accelerated by 5-7 days, the quality of the skins increased by 10%. The mortality of puppies in the experimental group was 5% less, and the number of puppies per female was 5 in the experimental group versus 3 in the control group. Electrohydraulic crushers for complex processing and "disinfection of meat waste from livestock farms, urban food waste, as well as peat, straw, pine needles, twig fodder and other organic products have already passed experimental testing, and in some cases, experimental industrial operation and have great prospects for wide industrial implementation.

All rights reserved by Trakonta 1996 – 2021